Description

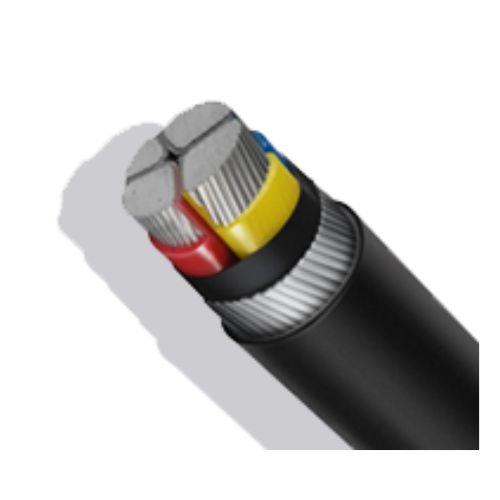

Parts of LT Power Cable:

You are given a choice to choose from different types of LT power cables. The basic and compulsory parts of power cables are as follow:

Conductor

The conductor is the material which carries current. It can be of different materials (Aluminum/Copper).

In the cable industry, it is preferred to use copper and aluminium conductors for LT power cables.

Conductors in these cables can be Stranded/ Solid/ Circular shaped-Aluminum/ Copper.

Insulator

An insulator is the part of the cable which covers the conductor so that the current won’t come out and create an electric fault. Insulators can be a wire (colour) or an insulating material.

The insulating material over the conductor can be PVC (Polyvinyl Chloride) and XLPE (Cross-Linked Polyethylene) or any kind of rubber.

The type of insulation depends on operating temperature.

Sheath

The sheath is basically a cover which protects the power cable. The material used in the sheath is polyvinyl chloride (PVC), rubber and often the same material as the bedding (tinned copper wire which acts as mechanical protection too).

The main work of sheath is to protect the cables from mechanical, climatic, electrical and chemical.

The outer sheath is protection offered to cable not much electrically but more mechanically.

Besides these, LT power cable has other parts too, which are armouring and beading (inner sheath).

Application:

LT power cable may be installed as permanent wiring within buildings, run overhead, buried in the ground or exposed.

Flexible power cables are used in mobile tools, portable devices, and machinery.

Features:

PVC/XLPE insulation is responsible for the fire-resistant feature.

Besides, it has many features as below:

Dielectric losses are very less in these cables.

LT power cable is flexible, lightweight, fire-resistant in nature.

These cables can carry high current with high short circuit rating 250°C as against 160°C for PVC.